Arm reduces Characterisation Turnaround Time and Costs with AWS Graviton Instances

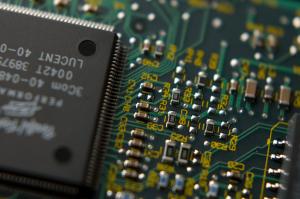

Arm is a leading provider of silicon intellectual property (IP) for intelligent systems-on-chip, creating IP used in the development of integrated semiconductor circuits. Arm estimates that 70 per cent of the global population uses its technology in some form of smart device or electronics.

Arm is a leading provider of silicon intellectual property (IP) for intelligent systems-on-chip, creating IP used in the development of integrated semiconductor circuits. Arm estimates that 70 per cent of the global population uses its technology in some form of smart device or electronics.

Previously, Arm has used an on-premises environment for EDA workloads, which has led to forecast challenges regarding compute capacity despite the company requiring a dynamic, flexible environment. According to Philippe Moyer, Arm Physical Design Group’s vice president of design enablement: “the on-premises compute was sometimes sitting idle until the need arose, which is why the scalability and agility of the cloud is a good solution for our business.”

The company was in need of improved agility in order to keep its development on schedule. According to Arm’s vice president of systems engineering Vicki Mitchell: “our data center was constrained in terms of scalability, and deployment of additional compute capacity would typically take one month for approvals and at least three months to procure and install hardware.” Such delays could break a project.

To solve these issues, Arm opted to move part of its EDA workload to Amazon Web Services (AWS). Initially running EDA workloads on Amazon EC2 Intel processor-based instances, Arm also used Amazon S3, combined with Amazon EFS for EDA data storage. Then, when AWS made it available, the Physical Design IP team began to run some of its EDA workloads on A1 instances powered by Arm-based Graviton processors.

AWS enables the design team to rapidly scale its EDA environment up or down from 5,000 to 30,000 cores on demand, resulting in drastically reduced turnaround time. The on-demand compute capacity also means engineers are far freer to innovate, compared to the on-premises environment. Finally, the Graviton processor family has enabled Arm to reduce its AWS costs by up to 30 per cent.